Industrial

Dust Collection

Spray-TEch

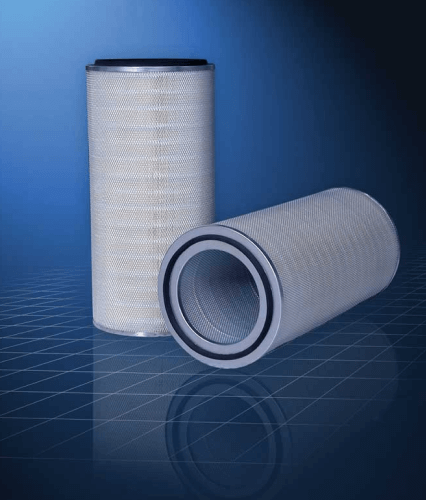

Spray-Tech/Junair dust collection system units are designed to increase the quality of the air and reclaim the coating material used in industrial and commercial finishing processes. Our cylindrical cartridges are used to trap overspray from the powder delivery system and through the operation of a reverse pulse of air allows the excess powder to be discharged into a collection tray for reuse.

The cost-effectiveness of our dust collection system and equipment is provided by the ability to filter air and reclaim a maximum amount of unused coating material. The dust collection system can be further enhanced by incorporating our patented industrial air movement and climate control systems.

What Is The Purpose of A

Dust Collection SYstem?

If you don’t have a dust collecting system, you could be putting your employees’ health at risk by exposing them to hazardous materials such as toxic fumes and particles. Air quality is an essential aspect of any shop; which, makes having a high-quality dust collection system critical. Many fields beyond the automotive arena utilize dust collecting systems, including woodworking, building, manufacturing, and industrial areas.

Fire Hazards

Health Hazards

How is the Dust Explosion Pentagon formed?

Standard (per Unit)

Features

- 12 Gauge Steel Cabinet Powder Coated White

- Reverse Pulse Plumbing and Valves Standard

- 6 Cartridge Filters – 99% Efficiency @ 0.5 Microns

- 5 HP Backward Inclined Aluminum Blower

- 1/4” Thick Steel Air Pressure Reservoir

- 3 Cubic Foot Capacity Dust Storage Drawers

- Our ETL-Listed High Efficiency LED Light Fixtures

Intuitive

ControL Panels

Spray-Tech/Junair dust collection system control panels are user-friendly and can provide incredible control over every facet of your entire finishing process.

We design custom software that allows the user to accurately control aspects of the booth with extensive time, pressure, and frequency settings.

In designing our control panels for industrial use and dust collection, we make sure to keep the operator in mind. With over 20 years of experience in building complete finishing systems, you can be certain Spray-Tech/Junair control panels will be easy to use and improve your workflow.

Dust collection system control panels come standard with all required safety features and include a Magnehelic gauge to let you know when to replace the filters on your system.

INtuitive Control Panels

Touch Screen TEchnology

Spray-Tech/Junair dust collection system control panels are user-friendly and can provide incredible control over every facet of your entire finishing process. We design custom software that allows the user to accurately control aspects of the booth with extensive time, pressure, and frequency settings.

In designing our control panels for industrial use and dust collection, we make sure to keep the operator in mind. With over 20 years of experience in building complete finishing systems, you can be certain Spray-Tech/Junair control panels will be easy to use and improve your workflow.

Dust collection system control panels come standard with all required safety features and include a Magnehelic gauge to let you know when to replace the filters on your system.

We have made developments to our controls to drastically reduce the amount of compressed air needed to operate our systems. Our smart pulsing technology helps to reserve energy by pulsing only when necessary. Thanks to this feature our dust collection systems can maintain the proper amount of static pressure, easier. This drastically cuts down on noise around the shop and also greatly extends filter life.

Included with our updated control panels is a smart shut-down feature. Many dust collection systems can emit dust on shut-down because static pressure is often cut abruptly, our smart shut-down feature gradually reduces static pressure after shut-down and maintains proper static pressure so the system is ready to begin operating immediately the next time it is turned on.

Your Dust Collection Purchase

Product Details

Standard Package

We go above and beyond traditional dust collection to make sure you get a bigger bang for your buck. Spray Tech/Junair dust collecting system is constructed with 12 gauge steel. Our dust collection system includes a reverse pulse plumbing standard, which helps collect the extra coating...

Cylindrical cartridge filters

The dust collecting system also includes six cylindrical cartridge filters which are 99% effective with particles as small as 0.5 microns. Our systems also capture overspray from the powder delivery system (which can be saved and reused). A Magnehelic gauge comes included as well, to inform....

Dust Collection Module DCM4500

Thermaire paint booths are an affordable option compared to other expensive models. However, it still provides your body shop with the best finishing technology available without compromise.

Upgrades

Your Package Options

The control panel on your dust collection system can be upgraded to our 6th generation touch-screen control panel, in which you will receive customized software that allows you to control every aspect of your booth including multiple variable frequency drives (VFDs). You can also control each of your finishing processes and modify your dust collection system to the type of dust you are collecting.

Another available upgrade is our patented industrial air movement system, also known as our QADs™ Auxiliary Air Movement System. Our QADs™ system helps to heat the air needed to cure the vehicles. Air encompasses the entire vehicle, including the lower panels. We offer different configurations, so you get what you need for your shop. The QADs™ system can interface with pre-existing air makeup systems.

Purchasing Questions,

Considerations, and Preferences

Manufacturing Considerations

- Does the manufacturer meet your shop’s needs?

- Do the parts they manufacture follow proper safety guidelines and OSHA regulations?

- Will the design of the dust collection system fit into my shop?

- Will there be any support after buying the dust collection system?

- Will replacement parts be available if something breaks?

Purchasing Considerations:

- Type of work environment

- How powerful a system is needed?

- How loud will the new system be?

- Is the installation process smooth?

Final

Details

Our Certifications:

With our smart pulsing technology, our system is relatively quiet. We follow some of the strictest guidelines that are set by OSHA, EPA, NFPA, NRTL, and our products are ETL and CTL certified. We proudly manufacture our products in the United States of America. We also assist in installing the dust collection units. Moreover, we offer scheduled maintenance on our products, emergency repairs, replacement parts, and equipment upgrades.

Satisfied Clients:

We work with many different industries and businesses. Some of our larger clients include Boeing, Tesla, Peterbilt, Disney, United States Military, Maaco, Michelin, Harley-Davidson, FinishMaster, and DuPont.